Some stretching occurs at this point and produces what is known as a shock line.

Deep draw stamping design guidelines.

After the first draw the blank diameter should not change.

Stamping design guidelines jonathan zhang 4 2.

Stamping processes the operations associated with stamping are blanking piercing forming and drawing.

A blank piece of sheet metal is positioned over a die and a punch is used to force the metal into the die and create a custom shape.

Wear resistance good conductive.

The information provided here is part of a larger discussion we provide in our downloadable metal stamping design guidelines.

Design open ended draw cavities for draw depth adjustment.

Technical design support for deep drawn stamping.

No matter how complex your design our can do philosophy enables us to produce.

Metal stamping design guidelines.

We also provide prototyping services and pre production samples of deep drawn shells.

By contrast soft tooling is used in processes.

Once the proper draw ratio is achieved metal will flow and the part can be drawn partially or completely off the binder.

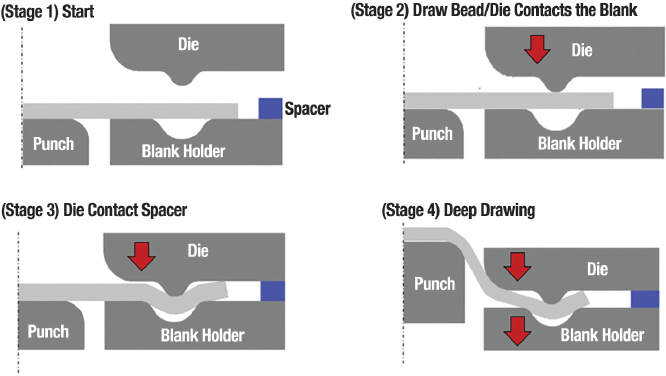

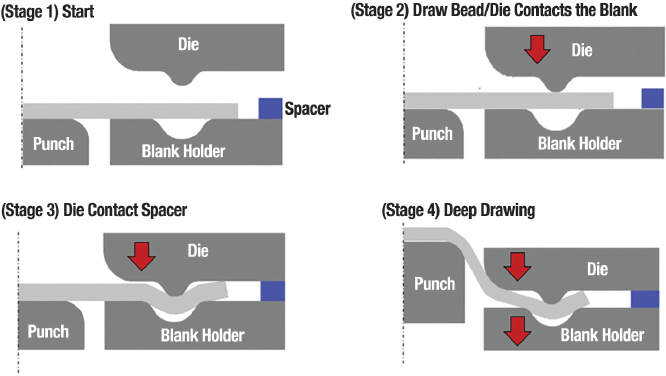

Anatomy of deep drawn stamping.

This type of tooling is used in making high volume part of one design.

The deep draw process is necessary for parts with a depth that exceeds their diameter like beverage cans deep pans assembly housings and other containers.

This is a pronounced area of.

The 2 stages of a draw are cupping and drawing.

When the punch first contacts the blank the nose of the punch initially embosses the material into the die.

Design for deep drawing sheet metal stamping dfm.

Larson tool works collaboratively with companies of all sizes providing guidance and cost effective high quality results with everything from precision metal stamping and forming to deep draw stamping.

Other guidelines to remember when the processing draw reductions are.

We offer pre design technical support to help you refine your designs for optimum manufacturability and cost effectiveness.

The process of deep draw stamping.

Metal stamping design guidelines metal stamping is an economical way of producing quantities of parts that can have many qualities including strength durability.