Vinyl mastering and lacquer disc cutting vinyl mastering consists of optimizing the final mastered song for the unique characteristics of the vinyl format which include low and high frequency treatment level adjustment groove spacing optimization and if necessary low end summing to eliminate undesirable phasing that can occur from stereo effects in the bass frequencies on vinyl.

Cut lacquers vinyl.

This is crucial for the vinyl s final quality since the lacquer errors amplify themselves during the process of galvanization of stampers for pvc moulding.

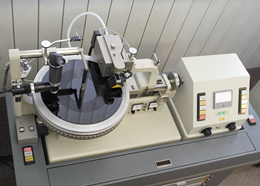

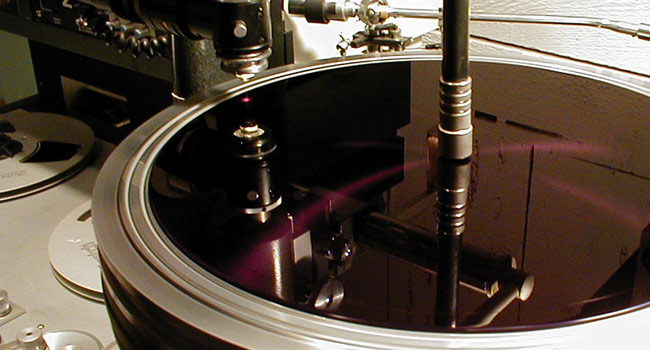

The cutting engineer plays the stereo tracks and uses a lathe to cut grooves into a blank lacquer disc.

This analogue mastering technique is widely accepted and used thanks to bigger number of lacquer cutting lathes available and the tradition of lacquer mastering through the years.

This is a technology developed in the mid 1980 s for cutting masters for record manufacturing.

These discs are the original copies of your music.

Although not comparable in scale frank remembers the dubplate scene as offering creative precedent for the current situation.

Instead of cutting into a blank lacquer grooves are cut into a blank copper disc via a specially equipped lathe.

Theoretically both sides of a lacquer could be used for cutting.

Acetate discs are used for the production of vinyl records.

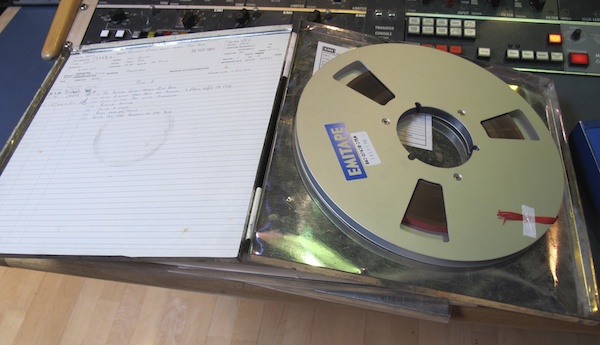

Lacquers are often cut by those who have made the vinyl master and all that is on the release is the mastering engineer s handle initial.

Lacquer technology cutting into lacquers is an older method of mastering for vinyl records but still has many supporters and fans.

This is the first and most delicate step in the record making process.

Since dmm was developed during the time period when vinyl was being overtaken by cassette tapes and ultimately compact discs as the dominant consumer music formats use and r d work was not extensively implemented in the.

Transferring your digital vinyl pre master to a lacquer is an extremely crucial process and has a major influence on how your vinyl will sound.

Sending your audio straight to a vinyl pressing plant and letting them handle the lacquer cutting is essentially the equivalent of that.

There s a company called vinyl recorder that developed a lathe to cut into plastic and cutting into plastic rather than acetate or lacquer meant that the discs lasted much longer into the thousands of plays.

However the manufacturer guarantees a flawless surface for only one side of the lacquer.

Cutting a lacquer disc.

I think this is going off on a dangerous tangent if left unchecked.

This stage involves audio engineers using a lathe machine and a very sharp gemstone to carve your music onto a flat lacquer coated metal disc.

See also lacquers and lathe.

An acetate disc is a type of gramophone record widely used from the 1930s to the late 1950s for recording and broadcast purposes and still in limited use today.

Once the music has been mastered the lacquer cutting can begin.